The 54th Annual Emergency Response Mine Rescue Skills Competition will be held Saturday, June 1, 2024 at Prairieland Park, Saskatoon.

The Competition Guidelines 2024 can be found HERE.

|

|

54th Emergency Response Mine Rescue Competition June 1, 2024 The 54th Annual Emergency Response Mine Rescue Skills Competition will be held Saturday, June 1, 2024 at Prairieland Park, Saskatoon. The Competition Guidelines 2024 can be found HERE.

Saskatchewan Mining Week May 26, 2024 Saskatchewan Mining Week 2024Saskatchewan Mining Week will be held May 26 - June 1, 2024. The week will culminate with the 54th Emergency Response Mine Rescue Skills Competition taking place at Prairieland Park in Saskatoon. Click HERE for a list of Mining Week events.

Saskatchewan Mining Week 2023Saskatchewan Mining Week was held May 28 - June 3, 2023. The week culminated with the 53rd Emergency Response Mine Rescue Skills Competition at Prairieland Park in Saskatoon. Following are the presesentations that took place during Saskatchewan Mining Week.

Saskatchewan Mining Week 2022Saskatchewan Mining Week was held May 29 - June 4, 2022. Click HERE for a Schedule of Mining Week Events. Following are the presentations that took place during Saskatchewan Mining Week. Foran Mining Corporation - Dan Myerson, Executive Chairman Prairie Lithium - Zach Mauer, President and CEO Saskatchewan Research Council - Mike Crabtree, President and CEO Carbon Capture and Storage in Saskatchewan - Past, Present and Future - Conway Nelson, Vice President Project Development & Advisory Services, International CCS Knowledge Centre, and Adlai Majer, Director of New Energy, Whitecap Resoruces Inc. Saskatchewan's Critrical Minerals - Essential to Global Security and Supply Chains Podcast - Panel moderated by Kelly Ogle CEO, Canadian Global Affairs Institute; Panel Members: Jerry Grandey, former CEO Cameco Corp and former Board member PotashCorp and Nutrien; Larry Long, Senior Vice President Operations, Potash, Nutrien; Alanna Koch, Board Chair, Global Institute for Food Security Restart of Cameco McArthur River and Key Lake Operations - Brian Reilly, Senior Vice President and Chief Operating Officer, Cameco Corporation Mosaic K3 Project & Potash Market Update - Kelly Strong, Vice President Mining, North America, The Mosaic Company

16th Annual Saskatchewan Mining Supply Chain Forum April 17, 2024 The 16th Annual Saskatchewan Mining Supply Chain Forum will be held April 17 & 18, 2024 at Prairieland Park in Saskatoon. The Mining Supply Chain Forum, hosted by SMA, SIMSA and Ministry of Trade and Export Development is the primary mining supply chain event in western Canada that brings together the Saskatchewan mining industry and local suppliers to enhance their global competitiveness and expand markets.

Following is a Draft Agenda: Tuesday, April 16, 2024

Wednesday, April 17, 2024

Thursday, April 18, 2024

58th Annual General Meeting March 27, 2024 The 58th Annual General Meeting will be held on Wednesday, March 27, 2024 at TCU Place in Saskatoon. Click HERE for the AGM Program. SMA Mine Safety Summit 2024 March 26, 2024 The SMA Mine Safety Summit - Technical Aspects of Mine Safety will be held on Tuesday, March 26th, 2024.. The format of the Summit utilizes case studies from SMA member companies and includes reviews of incidents. Mineral Exploration Expo November 27, 2023 Mineral Exploration Expo 2023 was held Thursday, November 9 at the Art Hauser Centre in Prince Albert. MinExplo Expo is an opportunity for primarily northern-owned businesses and community economic development officers to learn about mineral exploration programs and related business and employment opportunities that SMA member companies are planning for the upcoming 2022/2023 year. Following are the presentations from MinExplo Expo 2023:

Following is the Program and presentations for MinExplo Expo 2022:

5th Biennial SMA Environmental Forum October 17, 2023 The 5th Biennial SMA Environmental Forum will be held October 17 - 19, 2023 at TCU Place in Saskatoon. Related Documents:

2023 SMA GeoVenture Blog August 23, 2023 August 12 - 18August 12 and 13, 2023Spent a busy, informative, and fun, first afternoon and next morning learning about all that is geology, mining processes, and mining safety in Saskatchewan. Am suddenly proud of what the industry is doing and has to offer potential employees (ie. our students)! Thanks to our presenters for a relaxed day of learning. Now it is time to load the bus and….. Get our motor runnin' Head out on the highway Lookin' for adventure At whatever mines come our way Born to be wild…… First stop BHP Discovery Lodge All I can say is wow they treat their employees well! Top grades for planning a home away from home. The whole facility is designed to allow all the amenities employees might use in their home communities but it is all in one location! Almost like an all inclusive resort, except you have to go to work each day….. Gym, training facilities, court sports, outdoor track and training area, lounges for recreation, garden plots for those with a green thumb, and a top-notch theatre! I am sure I missed a few details but was very impressed. Thanks to BHP for the hosting us and providing a great lunch! Back on the bus and….. Yeah, we’re gonna make it happen Take mining in a love embrace Fire up the bus at once and Explode into Esterhazy Born to be wild……. Made our way to Esterhazy and were treated to a great homemade dinner of perogies, cabbage rolls, and sausage with salad at the local bowling alley. The meal set us up for a tour of the Saskatchewan Potash Interpretive Centre. Thanks to our guides, Richard and Oliver, who shared their vast knowledge of all the working parts and processes of the local mines while explaining the artifacts at the centre. And, back on the bus to the hotel….. Like a true teacher’s child We were born, born to learn Got to learn so much But now we wanna rest Born to be wild…… Thanks to Steppenwolf for the tune. Day one complete! August 14, 2023Video Blog: Potash - Conventional Underground - Nutrien Rocanville (forthcoming) August 15, 2023

|

|

|

D. B. Safety Solutions Inc.’s final “Introduction to the Industrial Supervisor” until further notice, none are scheduled for 2021. To register, simply email db.safetysolutions@sasktel.net Or call direct to 306-861-7093 |

$839 + GST

Location: Saskatoon Inn, 2002 Airport Dr.

Class Times: 08:00 - 16:00 Days One and Two

08:00 - 15:00 Day Three

The Saskatchewan Mining Association, the Saskatchewan Ministry of Trade and Export Development and the Saskatchewan Industrial and Mining Suppliers Association presents the Virtual Saskatchewan Mining Supply Chain Forum, on the rescheduled dates of December 2 & 3, 2020.

This Forum is the primary mining supply chain event in Western Canada that brings together the Saskatchewan mining industry and local suppliers to enhance their global competitiveness and expand markets.

Click here for more information and to register for the Forum.

NOTE: SMA Members will be sent a separate link to self-register for a complimentary registration.

Saskatchewan Mining Week was held from May 31 - June 6, 2020.

Following are Virtual Activities that occured during Saskatchewan Mining Week.

Saskatchewan Mining Week Virtual Launch Recording June 1, 2020Saskatchewan Mining Week Video - Mining: Essential to Local and Global Communities

John T Ryan Safety Awards Virtual Presentation Recording June 1, 2020

John T Ryan Safety Awards Powerpoint

APEGS and Saskatchewan Geological Society webinar on GeoExplore Saskatchewan website June 3, 2020

Saskatchewan Mining Week Potash and Uranium Commodities Update Webinar June 4, 2020

Following are links to the presentations from the 54th SMA Annual General Meeting, Wednesday, February 26th, 2020 in Saskatoon.

Plenary Session 1:

Plenary Session 2: Deloitte Mining Insights: Tracking the Trends 2020 - Gerhard Prinsloo, Deloitte

Following is the 2019 SMA GeoVenture Blog that took place August 17 - 22.

GeoVenture 2019 has officially launched! Our first day included our orientation workshop, getting to know each other and our first meal together at the Saskatoon Inn. Our travelling group this year includes 13 teachers, Dillon Johnstone from the Saskatchewan Geological Survey, and the SMA Team – Pam Schwann (president), Brad Sigurdson (vice-president) and Terry Johanson (Education Outreach Coordinator). Our workshop also included Jessica Theriault from Mosaic.

GeoVenture is a cornerstone of the SMA’s Education Outreach programs, which also include lesson plans, workshops, resources and a new teacher Catalyst program. The catalyst program gives GeoVenture alumni the chance to share their new knowledge with other teachers!

Our group learned so much from Dillon about the geological events that formed our province. Saskatchewan is pretty flat today, but our land was formed from huge mountain-building events and erosion. Dillon showed us that the mineral resources we mine were formed millions of years ago – the metals in the north are embedded in rock 1 to 2 billion years ago, while the potash in the south was formed less than a half a billion years ago. Dillon and Pam capped his presentations off by teaching us how to classify rocks using our rock identification kits.

Did you know that you are more likely to have a lost-time safety incident working in health care than if you work in the mining industry? We were surprised to learn that government workers also have a poorer safety rating than mining! Pam, Brad and Jessica Theriault introduced us to the mining industry in Saskatchewan. Some fun facts are that mining is the fourth highest mineral producer in Canada, we produce 32% of the world’s potash and 22% of the world’s Uranium, the mining sector is the #1 industrial employer of indigenous people, and Saskatchewan is the #1 mineral investment attraction in Canada. Most of us had no idea that mining has such a huge impact on our economy. The future of mining in Saskatchewan is strong, despite current commodity prices. Our world’s future population will require more food and more clean energy, which means more potash and more uranium demand. This means that the sector continues to invest in exploration to ensure long-term availability and access to resources.

It is pretty easy to see how we can include information and activities about mining into science classes, but today we were able to see how important mining is to our society as a whole. Infusing discussions and decision-making ideas into social studies is just as important. Our minds are already full of possibilities – we can’t wait to learn more through the week on this grand GeoVenture!

.jpeg)

We started the day learning about solution mining in Saskatchewan. Our potash samples, that we had previously started to dissolve the night before, had supersaturated the water. We needed to filter off the impurities (clay, iron oxide, and other excess undiscovered matter) to gain a purer product. After filtering, we took a sample of water and recrystallized the potash, using an ice-water bath. Potash crystallizes as a lower temperature than sodium chloride, so we could extract the potash in crystal form. This is similar to how they extract potassium chloride in solution mines. They collect the solution into tailing ponds and as the temperatures drop in they are able to scoop the crystallized potassium chloride off the bottom of the pond and recycle the water for future solutions. For further enrichment in a class (Chemistry 30 and Physical Science 20) it could be possible to test the crystallized potash to confirm it is potassium and not sodium through a flame test.

We then learned about uranium and uranium mining from NexGen. Troy Boisjoli (Vice President, operations and project development) and James Hatley explained how Uranium is discovered in Saskatchewan and the financial and scientific effort it takes for Uranium exploration. He also focused on the impact NexGen is having in Saskatchewan and how all of the funding being put into Saskatchewan is completely sourced out of Province. NexGen is also working with the Dene community very closely, forming strong relationships with its members. NexGen has a strong program that lets 20 young people working in all of the different facets of mining so they can experience many different careers. From this group of individuals, they award bursaries for schooling and have sent many kids to university. They have also given much back to the community by providing jobs and providing a breakfast program to the school. Uranium mining and exploration have excellent curriculum connections to waves (EM radiation and gravity) and chemical equilibrium(redox reactions).

Wrapping up our initial learning time in Saskatoon, we set out for BHP Jansen Discovery Lodge and started our adventure. Maury Simoneau led us on a tour of the state-of-the-art Discovery Lodge and WOW. It was massive. It had a gym, a theatre, and you could order almost anything that you wanted to eat! So amazing. BHP has invested 250 million dollars into this site without a cent of potash being taken from the ground. The site can hold 2500 people when moving into stage one of setting up the potash mine. They pride themselves on their accommodations and forward thinking in the company.

A long bus ride took us to Esterhazy’s potash interpretive centre next. John and Richard lead us through this museum in great detail. It was very interesting and really helped us learn about potash before we could take our mine tour in Rocanville. We finished off the day with an amazing Ukrainian supper of sausage, perogies and cabbage rolls and called it a night at the Canalta in Esterhazy.

We had a great sleep and a bright and early breakfast at the Canalta Hotel in Esterhazy before hitting the road towards Rocanville at 6:45 am. Along the way, Pam showed us the new K3 site near Esterhazy, which has an exceptionally tall and impressive head frame. Once operational, potash from this new facility will be transported by conveyor belt to the K1 or K2 sites to be milled. As we continued our journey, Pam briefed us on the geological features in the area such as the Qu'Appelle Valley, which developed as the ice melted and retreated during the end of the last ice age.

We arrived at the Scissors Creek site at the Nutrien Rocanville mine around 7:45 am and were informed of the history of the mine and welcomed by Calvin, Amanda, and Leland, who would be leading us on our tour underground. Safety in the mines is of utmost importance, so we suited up into our safety gear first thing. We all looked great in our reflective vests, steel toe boots, goggles, hardhats, and gloves. In addition to the safety clothing, we also had earplugs for hearing protection, and each wore an oxygen breathing apparatus around our waist for use in case of emergency.

After getting geared up, it was time to load into the cage to proceed underground. The cage is like a giant elevator that can comfortably carry 40 people down into the mine. The spectacular ride down took about three minutes and brought us a kilometre below the surface. The size of the underground portion of the mine is massive, taking up about the same amount of space as the city of Saskatoon and boasting the title of the largest potash mine in the world! Approximately two kilometres of fresh ground is opened every day and 200 train cars full of potash are removed - amazing!

During our tour, our guides told us that the mine houses twelve miner machines, each worth 15 million dollars. We had a chance to watch the "Leopard" miner in action as it worked on drilling out a new room in the mine. Afterwards, we had the opportunity to gather samples of potash to bring back to our communities and show to our students. We also checked other areas in the mine, such as the shops where equipment is assembled and maintained, and the refuge areas where workers go in case of emergencies or power failures.

After coming back to the surface, we were treated to a delicious lunch on the mine site and had the chance to learn more from our guides and other experts from the mine. One interesting conversation that came up was about the recent 4.1 magnitude earthquake that occurred nearby. Contrary to what was said on T.V., the tremor wasn't felt underground at the mine, and the power outage on site occurred because of an automatic breaker jump.

We are now en route for Willowbunch where we will have a BBQ supper, get an overview on coal mining, and have a good night's sleep before another jam-packed day tomorrow at the Poplar River mine and Castle Butte!

.jpeg)

Day 4 - Coal Strip Mine, CCS Presentaiton and Castle Butte, August 20 - Janna Varga (Air Ronge) and Matthew Kampman (Regina)

Today we continued our Geoventure across Saskatchewan. Yet another early morning began as we loaded the bus at 6:30am in Willow Bunch, SK. A last minute walk brought us to an interesting local museum. There we learned of Edouard Beaupre, a local Métis man who had grown to be 8’3”. Edouard was also known as the Willow Bunch Giant... be sure to check out the museum if you’re ever in the area. We then continued on to Coronach for a breakfast at Deb’s kitchen. The cozy dining area, company from Poplar River employees and a hot buffet was well received by all GeoVenturers and Mine employees.

8:00am Upon our arrival at Poplar River Mine we geared up in our PPE (personal protective equipment) and headed to the main building. Ready to learn, explore and sample all that this coal mine had to offer. After a few more introductions we were directed to a meeting room. We settled in for a short, animated safety video that was quite engaging, and then filled out our visitor forms. The mine sites’ employees were obviously proud and ready to share their profession with us, so we all moved on with the tour.

We toured the main building, learning of a mammoth tusk that was found on one of Poplar River sites. Fossils are always cool and they had their fossil proudly on display. We then moved on to their enormous shop.

Pictures were taken and everyone was interested and excited. Everyone loves massive equipment and Poplar Ridge mine has some of the best I’ve ever seen! A giant caterpillar that was having the tracks replaced, 2 loaders with tires 10’ tall and 2 massive coal haulers that you would have to see to believe! This equipment did not disappoint.

Next we headed to the bus to view the Dragline in action, see the reclamation on past sites and of course tour the open pit. Our Poplar Ridge tour guides took turns handling the bus mic and described and pointed out reclaimed fields, past areas that were mined and other interesting facts along the way. We watched the Dragline in action and I’m sure more than a few of us wished we could operate that machine. At the pit we were encouraged to ask questions, explore and collect our own coal samples.

After filling our pockets (Ziploc bags) we headed back for lunch with the crew and a Carbon Capture presentation... more on that from Matthew Kampman of Regina, SK.

Our tour of the Poplar River Mine was capped off with a scrumptious lunch courtesy of the mine, and an engaging presentation from Corwyn Bruce, one of the lead engineers of the carbon capture and storage (CCS) project at Boundary Damn 3. Since the project’s success Corwyn has taken his expertise to an international audience; consulting with coal fired power plants in other countries who stand to benefit from CCS facilities.

Through CCS, Corwyn's team has reduced the CO2 emissions of BD3 by 80 - 90% depending on operating conditions. What an achievement! It remains to be seen whether Bruce's team will be given the green light to outfit the Shand coal fired power station outside of Estevan with the same technology. Nonetheless, CCS has the potential to be implemented in coal fired power plants all around the world. A CCS facility that is bigger than BD3's has already been implemented in Texas. It was a pleasure to hear Corwyn speak and we wish him the best in his efforts to implement CCS technology at home and abroad, helping to both protect the environment and create meaningful employment for those who work at CCS facilities.

After the Poplar River tour we headed east to Castle Butte, part of the Big Muddy. Since I don’t want to ruin your first experience seeing this geographical sight, I’ll simply quote a tour mate...According to James Armstrong of La Ronge, SK, “Castle Butte is cool in every single way. Erosion can’t bring it down.”

Looking forward to Day 5 a potential Uranium filled wonder.

After an early morning wake up call, we met in the lobby at 6AM to head over to Westwind Air terminal to catch our 6:30 flight up to Cigar Lake to begin our day learning about Uranium. Our pilots were very friendly and had breakfast provided on the hour and forty-five minute flight into Northern Saskatchewan. Upon landing we boarded the bus that then took us to Cigar Lake mine. Once there we had a safety orientation and a quick presentation about how the mine operated from the mine operations manager as we had our morning coffee. After the presentation we left to get geared up so we would be safe when we went underground. This included white Tyvek overalls, little cloth booties to make the steel toed rubber boots more bearable, hardhat with lamp, gloves and of course safety goggles. Our guides Stephanie and Imre then took us to the cage that would take us down 480m into the mining tunnels. Although a bit cramped the ride down was quick and cozy. What a difference between the uranium mine and the potash mine. Instead of a dry, warm environment like the potash mine, this was wet and cold. All of the walls were reinforced with concrete and we got a close up view of the New Austrian Tunneling Method. We then got to see the uranium miner (in fact were on it!) and got an outstanding explanation of how it worked. The miner blasts the uranium out of its cavities with water pressured at 15 000 PSI. That’s enough pressure to cut steel! The slurry is then pumped to the surface where it is loaded into specially designed containers that are then trucked to McLean Lake Mill for processing. After returning to the surface we got bussed back to the airport and had a quick lunch on our 15 minute flight to Points North.

At Points North we had a bus waiting for us that took us to McClean Lake Mill. After yet another safety presentation, we got our safety equipment and began our tour of the mill. We broke up into two groups and the general manager, Vincent, and the operations manager, Todd, did a great job of showing us how the milling process works in a short period of time. Essentially, the mill concentrates the uranium that arrives from Cigar Lake and prepares it for transport for refinement in Ontario. Another significant role of the McClean Lake mill is to manage the tailings that are produced from the milling process and we visited the tailing management facility. It was obvious that Vincent was very proud of this facility and he said that no other mine in the world is using these techniques. It was an impressive operation. We went back to the safety station, returned our equipment and then had some light refreshments before jumping back on the bus for the bouncy bus ride back to the air field. We boarded the plane and were back in Saskatoon by 6:30 to conclude our whirlwind day.

There was so much information provided on this day that could be used in the science classroom – especially in chemistry – but when one considers all of the economics that are involved in this industry and the socioeconomic impacts that uranium has on local, provincial and world communities, one could use this information in the social studies classroom as well. It was a great way to end our last full day of the tour!

After an amazing and exhausting week blitzing around Saskatchewan's major mining operations, it was time for "Diamond Day". We started the day with yet another delicious breakfast, after which we were treated to a nerdtastic presentation on kimberlite mining, courtesy of Rio Tinto and Warren Riemer, one of two impressively tall geologists in the room.

What is kimberlite you ask? In addition to being the likely name of the next Kardashian baby, it's an igneous rock that can contain diamonds; the hypothetical Kardashian baby would likely have its diamonds on the outside.

We learned that the diamonds in kimberlite were formed some time in the late Cretaceous. The hardness of diamonds, setting the high-bar of 10 for the hardest mineral known, is one of its coolest properties! Even though it makes perfect sense, it blew my mind to learn a 30 centimeter drop is enough for one diamond to chip another...completely shatters the trope of a jewel thief doing high impact acrobatics with a pilfered sack of jostling diamonds at their side - they would be ruined!

The value of diamonds comes from their aesthetic, and more importantly, their rarity. Unusual size or rare color can greatly increase value. For instance, Argyle diamonds have a slight twist in their carbon matrix, giving them a rare pink hue. This makes them incredibly rare and valuable!

A portion of the talk was about the FalCon Diamond Project, the exploration of the Fort al a Corne site to determine the grade and quality of the kimberlite 400 meters below. Princess Leia was instrumental in this - her ability to extract 1 ton of ore every 2 minutes made her uniquely suited to the job. She didn't use the Force to do this, she used quality engineering, since she happens to be the "industrial mining cutter" Leia, not the "Han Solo's crush" Leia.

We learned the biggest obstacle for making a profitable mine was the removal of the overburden (that’s the technical term for all the earth on top of the desired ore). Here's hoping the exploration goes well, and the tens of millions of dollars Rio Tinto spends on the site bears fruit!

In the afternoon we went over to SRC Diamond Lab to meet a third impressively tall geologist. It's at this point that I start wondering if geologists are a tall alien species that came to earth to study it. It casts the Willow Bunch giant in a new light… I feel he was likely one of the early alien explorers.It was incredible to learn that the Saskatoon SRC Diamond Lab is the world's largest diamond lab! Kimberlite from all over the world is assessed there, at an even greater efficiency than the lab in Kimberley South Africa, kimberlite's namesake! Without going into too much detail, this facility is a hotbed of expertise and innovation. I loved seeing the diamond indicator minerals under the microscope - gimmie shinies!

On that note, it was interesting to put the entire vast scope of global diamond production in terms of "finding rare shiny pretties". Every other mining industry we observed revolved around immediate pragmatic use. The diamond market's premium on aesthetic and rarity make their economics closer to a type of collecting, as exists with comics, baseball cards, and stamps: their value is almost entirely subjective! When squaring the colossal efforts and costs with the final product, it's surreal... and worth thinking about.

After the tour was done, our week-long Geoventure tour was concluded. It was a wonderful experience from top to bottom, filled with hospitality and good faith.

The 51st Annual SMA Emergency Response Mine Rescue Skills Competition was held Saturday, June 1, 2019 at Prairieland Park, Saskatoon. Click here for the 2019 Competition Guidelines.

Click here for the Competition results.

Click here to read the The Scoop - 2019 SMA ERMRC Newsletter

Saskatchewan Mining Week May 26 - June 1, 2019. Theme - Mining: Supporting Local and Global Communities.

Click here for a schedule of Mining Week events.

Mining Week Presentations included WIM/WiN Saskatchewan Networking Event

The 11th Annual Saskatchewan Mining Supply Chain Forum co-hosted by the Saskatchewan Mining Association, the Saskatchewan Industrial and Mining Suppliers Association and the Saskatchewan Ministry of Trade and Export Development took place April 3 and 4, 2019 at Prairieland Park in Saskatoon, SK.

The Forum provided information on current mining operations and projects in Saskatchewan and the related supply chain opportunities for manufacturing companies.

Click here for the Agenda.

Following are presentations from the Forum:

Tom Olson, The Mosaic Company - Next Generation Technology and Innovation

Mike Elliott, BHP - Jansen Project digital strategy

Jeff Wagner and Josh Dodd, Nutrien - Potash Operations, Capital and Procurement

Peter Haugen, The Mosaic Company - Operations/Project Updates

Matthew Wood, Western Potash Corp. - Western Potash Milestone Project

Rhea Brown, SaskPower - SaskPower's Path to 2030

Thomas Papst, K+S Potash Canada - The Saskatchewan Mining Supply Chain Forum

Brian Beverage, MNP - Block Chain Technology Overview for Mining Industry

Diane Cameron, Natural Resources Canada - Small Modular Reactors (SMRs)

Terence Stechysin, Competition Bureau Canada - Bid-Rigging, Collusive Behavour & Compliance

Troy Baril, Miller Thomson - Prompt Payment Workshop

Brian Warbey, Saskatchewan Ministry of Finance - PST Workshop

SMA Environmental Forum 2018 is a professional development opportunity for environmental practitioners in the mining industry, consulting businesses, post-secondary researchers and government. With changing regulations and evolving technology it is important for environmental professionals to keep current, and move forward, in developing and identifying best practices related to environmental sustainability.

Following is the Agenda along with the presentations:

2018 Environmental Forum Agenda

Brehm_Judd-Henrey-Oct 17-A-1400-1430

Fernandes_Lucas-Oct 18-A-1400-1430

Ferris_Ferguson-Oct 18-A-1430-1500

Heffner_Skinner-Oct 17 -B-0830-0930

Hinz_Fullarton-Oct 17-A-1130-1200

Jeerakathil-Keynote-Oct 17-1200-1230

Page_MacBride-Oct 17-B-0930-1000

Pedler and Meadows 2018 SMA paper_FINAL

Pedler_Meadows-Oct 17-A-1330-1400

Searcy_Benson Oct 17-0930-1000

Zwarich_Message-Oct 17-B-1400-1430

Following is the 2018 SMA GeoVenture Blog August 19 - 24

Day 1 Orientation and Welcome BBQ, August 19, 2018

GeoVenture 2018 kicked off with an Orientation Workshop which included Introductions; Itinerary review; Curriculum Link Outline; Introduction to Rocks and Minerals; Overview of Saskatchewan Mining Industry; distribution of curriculum-related material.

The day finished off with a Drill and Grill dinner at Saskatoon Inn attended by SMA Board members.

Day 2 Potash - Solution (Mosaic Belle Plaine and Potash Interpretive Centre), August 20, 2018

By John Nicholson, St. Joseph High School, Saskatoon and Majak Mapiour, University of Saskatchewan, Saskatoon

We had a nice breakfast at the Saskatoon Inn and boarded the bus for the Mosaic potash mine at Belle Plaine. This mine is the largest solution mine in the world and produces more potash per year than the United States. It also generates its own electricity and consumes as much natural gas per year as the city of Moose Jaw. The 64 km2 mine site has about 1900 km of underground pipes that pump hot water down 1500 m to dissolve the potash. Belle Plaine mine consumes 19 000 L per minute (24/7) and all is kept on site.

What is potash?

Potash is the name given to potassium compounds and potassium containing materials, the most common of which is KCl. The name comes from the middle Dutch potaschen which means pot ash, referring to its original production of soaking wood ash in pots. The name of the element potassium comes from potash. Potash ore is a mixture of KCl, NaCl, Fe2O3, clay and other trace salts.

Potash Mining

There are two ways to mining potash: conventional mining and solution mining. In Mosaic Belle Plaine solution mining is used. Natural gas is burned to turn water to steam. The steam is put through two turbines to generate electricity. 90% of power needed to run the plant is produced on site and the rest is supplied by SaskPower. The steam exits the turbines as hot water, which is then pumped into the cavern to mine KCl. The recovered brine solution from underground is sent to either the refinery or the cooling ponds.

In the refinery, the brine solution is pumped to the evaporators (8 in total), where steam is used to evaporates some of the water causing the NaCl to settle out of the solution. Then the stream is directed to the crystallizers to recover KCl. Subsequently, the wet KCl is dewatered, dried, sized, compacted, and/or stored. The cooling ponds use natural evaporation to settle out the KCl. Two dredges are used to recover the KCl from the ponds.

Potash Interpretive Centre, Esterhazy, SK

After our drive from Belle Plaine Potash Mine, we arrived in Esterhazy at about 7:00. We were treated to a wonderful, homemade Ukrainian supper of perogies, cabbage rolls, and Grayson sausage at the Esterhazy Bowl Arena. Socializing and interacting with the others in our group was a very nice touch to the evening as we all sat together at one large, square table, where we were served our supper.

We then walked over to the Potash Interpretive Centre. Outside of the centre there was a tall, 20 foot statue of a miner and an old train car out on the front lawn. When we entered the centre, we were greeted by our tour guides who were retired employees of the mine. We learned about the backbone of the Esterhazy economy, which is potash.

The interpretive centre is a great place to go to learn about the history of the potash industry and how it is important not only to the people of the area, but also all around the world. The information was displayed through murals, maps of the local mines and the patterns they used for mining, a life-sized diorama of the area being mined, miniature models of the equipment used, and videos.

We learned about the construction of the mines and how the technology has changed throughout the years. Where once there was a lot more physical labour, many of the mines operations are carried through by computers and automation. Safety measures are also considered more effectively than in the past.

The Potash Interpretive Centre is an excellent place to visit to experience what a working potash mine is like, without actually being able to visit a mine.

Day 3 Potash – Conventional Underground (Mosaic Esterhazy K1 & K2), August 21, 2018

A Mine Called K1

By Melanie Charnetski, Eaton School, Eatonia; Lanna Abbott, Lumsden High School; Violet Dubitz, SMA

Now this is the story all about how,

We learned about mining underground.

We’d like to take a minute,

Just sit right down,

We’ll tell you how we became the queens of a mine called K1.

In Southeast Saskatchewan, born and praised,

In Esterhazy is where spent one full day.

Gearing up, maxin’, descending all cool,

Traversing the tunnels, gettin’ all schooled,

When a couple of guys, who were up to some good,

Took us on a tour of their neighbourhood.

We got in some good sights, and we weren’t even scared,

Brad said, “Take as many potash samples as you dare.”

We whistled for a ride, and when it came near,

We thought to ourselves, “What a career!”

If anything we could say this trip was rare,

And we thought, “Time for the mill, yo holmes, to the stairs!”

We arrived at the mill around 12:08,

And we learned about size and importance of grade.

They showed us their kingdom, our tour was done,

Thank you, best wishes to the mine called K1!

Mosaic Esterhazy K2

Michelle Peters, Thom Collegiate High School, Regina and I (Mick Rissling, Martin Collegiate High School, Regina) decided to express the processes we learned about traditional underground potash mining and potash chemistry from the Esterhazy K2 mine in song form. You may wish to listen to it by itself or as an accompaniment (or epic song battle) to the song done by our colleagues in their K1 mine experience. Enjoy!

Esterhazy Rhapsody (sung more-or-less to the tune of Bohemian Rhapsody by Queen)

Is this the real life?

Is this nerd fantasy?

Down in K2 mine,

3.3 x 103 feet from reality.

Open your eyes,

there are no skies to see.

I am just a poor teacher,

I need some good PD.

Because it’s easy come, easy go,

we’ll again be high but now we’re low.

The one way that the fans blow really, really matters to breathe.

To breathe.

Mosaic, protects a man.

Put a hard hat on his head,

Safety trained so he’s not dead.

Mosaic, K3 just begun,

To no longer have to throw water all away

Mosaic, oooooh

Still need to make it dry.

If I’m not up the shaft this time tomorrow

Come on down, come on down, I’ll be in the refuge.

Clocked in, time to descend

My ears poppin’ all the time.

Steel-toe boots caked with brine.

Good-bye everybody, I’ve got to go

Gotta leave surface behind and face the face.

Mama, ooo (there is no way the wind blows)

The pressure is real high,

I sometimes wish I’d never come down at all.

We see high-grade potash in the rock,

Dig it out, send it up, will you do the miners’ tango?

Blades spin as fast as lightning, with PPE it’s not frightening

Esterhazy, Esterhazy,

Esterhazy, Esterhazy,

Esterhazy Mosaic Co. Mosaic Co.!

It’s just a mixture, gotta separate it

it’s just a mixture, from the Elk Point Sea.

crystalline compounds, evaporation processes.

K-C-L , K-2-O, just let it go.

so-di-um - electrons let it go - let it go!

so-di-um - electrons let it go - let it go!

so-di-um - electrons let it go - let it go!

We will not let you go (never)

Never let you go let me go

Never let me go ooo

No, no, no, no, no, no, no

O chemistry-a differential density-a help-a-me-a let it go!

Flotation has aeration and ions for me.

For me

For me

So you think you can split me and sell me by size?

So you think you can dissolve me and leave me to dry?

Oh baby, I just need to be compacted, baby.

Just gotta get sold, just gotta get shipped outta here.

Ooh yeah, ooh yeah,

Potash really matters,

Botanists can see,

Potash really matters, to plant chemistry.

All the ways the food grows.

Day 4 Coal - Westmoreland Coal Poplar River Mine and Castle Butte, August 22, 2018

The sleepy group of 2018 GeoVenture participants awoke to a beautiful crisp yet sunny day in the lovely community of Willow Bunch, Saskatchewan. After a brief meal at the local restaurant we ventured out to ‘meet the giant’ nearby, Mr. Edouard Beaupre. Standing over 8 feet tall was an impressive statue of his likeness, but nowhere near the size of ‘Great Gus’.

Great Gus is the smaller of two giant draglines that are the backbone of the Westmoreland Poplar River coal mine. With a boom arm measuring 140 meters and a reach of 110 meters, this behemoth moves earth like a champ. If this were parked at one end of Mosaic stadium it could reach the goal post at the other end! It has the power to dig a typical basement in two swipes of its giant bucket, with each swipe carrying 70 cubic meters.

Upon arriving at the Westmoreland facility, we signed in and were given a very thorough orientation and safety talk, complete with a professionally produced animated video. We all donned our Personal Protective Equipment (PPE) and off we went to board the bus. The first stop was to see the coal seam and get out to walk in the pit. We were treated to seeing the water truck go by and water the coal in an effort to keep the dust down. We were also given bags to collect our very own coal samples, and had a group picture taken in front of the coal.

The seam of coal is typically about 4 meters deep, and is covered by about 30 meters of overburden. It is the job of Great Gus to remove this overburden. The giant loaders and haul trucks do the rest. We watched a truck get loaded while we were there, hauling away about 140 tons of coal which is about 5 bucket loads from the loader. We then followed the truck out of the pit up a ramp that has a maximum grade of 6 percent. This means that for every 100 meters of travel, the ramp can only rise by 6 meters…but when you are hauling that much weight it is a pretty good feat. Upon leaving the coal pit, the trucks travel approximately 5-10 minutes to the hopper where they unload all that coal so it can be loaded into the train for delivery to the power plant.

At the loading station, trains come to the plant to be loaded with coal destined for the power plant. After the coal is hauled from the pit to the hopper, the truck unloads the coal and it is crushed to a more uniform size around 6 inches. Then it is loaded onto a series of train cars (21 in total), and hauled to the Sask Power coal generating power plant. This plant has two turbines and each one has a capacity of 315 megawatts. The 630 megawatts of power generated at this plant represents about 20 percent of the total power that the province of Saskatchewan uses. Two locomotives are owned by the company, and each of the rail cars holds about 90 tons for a combined total of about 2000 tons per train. That coal is typically used by the power plant in about 3 hours, after its been crushed at the plant into a fine dust so it can be sent to the furnaces for combustion to power the turbines.

Our bus headed out to take us to see the dragline next, appropriately named Great Gus. Another dragline is the 400 foot dragline, but at the time was undergoing an 18 million dollar service and was not operational, but it is the largest dragline operated in Saskatchewan. The main purpose of the draglines are to remove the approximately 30 meters of overburden, and access the coal seam, but the dragline doesn’t actually dig the coal. We all had an opportunity to see the spare 100 ton dragline bucket, and had another group picture done in front of this giant ‘shovel’.

We were able to see the dragline from two angles, and after leaving the second pit we headed to the main facility again to tour the maintenance shop. Maintenance is one of the largest expenses for the company (after wages) and preventative maintenance is performed on all the equipment regularly. All equipment is washed before it is worked on, and the mechanics are generally all journeymen heavy duty mechanics. The last part of our tour consisted of a lunch with many of the company leaders and it gave us an opportunity to ask many great questions. The knowledgeable staff made the tour not only safe and informative, but also exciting. We learned about their drone technology for mapping the site, the GPS technology that the operators use, and some more history of the company, both at this mine and others that they operate.

One thing that was stressed throughout our entire tour was the importance of site remediation and reclamation. Westmoreland works consistently with local land owners and government to ensure all regulations are being met. They reclaim all land to a state very similar to what it was prior to the mining, and most of it is returned to farmland and eventually sold to local farmers once the coal has been removed. The entire operation was impressive to see, very educational, and certainly gives us educators who were on the tour a lot to talk to our students about.

Castle Butte

By Debbie Peterson, Kyle Composite School and Lee Jacobson, North Park Wilson School, Saskatoon

Coming across the flat prairie from the southern part of Saskatchewan, we followed the long road into a wide open valley formed by glacier melt water channels. It was flat except for a tall castle which appeared before our eyes. It was in the middle of nowhere and rose up tall, dry, orange, brown, and beige with sage, dust, and some grass around it. It was full of horizontal and vertical lines covering the whole surface. Upon further examination, there were some caves around the base. Why was it here? What made the lines crossing the surface of the castle? We needed to interpret the geology of this formation.

Our guides Svieda and Pam were a wealth of information sharing that the Castle was indeed formed during the Upper Cretaceous period where the land was mostly covered by rivers, streams and swamps. Sediments deposited at the bottom of the water 75-55 million years ago created the sedimentary rock. As the surrounding rocks were eroded away, a butte was left behind (a butte is a flat-topped hill of soft rock with a hard-protective rock on top). The soft rock does not erode due to the hard-top surface. In the sedimentary rock, there is sandstone and traces of iron. The iron shows up in horizontal bands that create protruding ledges as the sandstone erodes. The vertical lines covering the butte are a result of water and weather eroding the sandstone.

Some of our group walked around the circumference, some explored the caves, and others climbed the top to enjoy the beautiful vista. There was an opportunity to express our artistic talents on paper showing our impressions of the wonderful Castle Butte.

.jpg)

Day 5 Uranium - Cameco Cigar Lake and Orano Canada McClean Lake Mill, August 23, 2018

Cameco Cigar Lake Mine

By Karen Kennedy-Allin, Weyburn Comprehensive and Shelly Stamm, Central Collegiate, Moose Jaw

We started the day by meeting down in the lobby of the Saskatoon Inn at 5:45 am. Even though it was so early, we were all on time! We divided ourselves into cars and Pam lead us in a convoy to Westwind Airlines. We checked in and waited our turn to board. Breakfast was waiting for us on the planes.

The flight was beautiful, although it was a bit smokey to start with due to the fires in BC.

Pam gave us a lesson about the Athabasca basin while we were on our way. Click here and here to see geological maps of Saskatchewan and the Athabasca Basin similar to what Pam was showing us.

We arrived at our northern destination about an hour and a half later. It was interesting to note that the runway was a dirt runway, but it was a smooth landing nonetheless. At that point, we were welcomed by a friendly employee of Cigar Lake Mine.

A school bus was waiting to take us to the mine site. The views were spectacular! We had seen many of the lakes from the airplane, but it was even better up close. We noticed that the trees were not quite as tall as trees further south. This is likely due to the colder climate and soil conditions compared to further south.

Our orientation was led by the manager of the site, Jeremy Breker. During the presentation he emphasized safety above all.

Cigar Lake has a unique resource. It has the highest grade uranium mine in the world.

Jeremy gave us an overview of what we would be seeing and we were on our way to put on or PPE. We had booties, steel toed rubber boots, a white Tyvex jumpsuit, helmet and safety glasses.

All of our tours have involved two people from the mine to lead our groups. One person describes what we are seeing and the other person follows behind answering questions and makes sure no one gets left behind.

We were taken to the elevator shaft which was also referred to as “the cage”. The ride down was exciting and quite smooth. Our tour guides took us to several places including a refuge station that also serves as a lunch room. Workers must clean their boots before entering and remove their safety helmets, gloves and wash their hands before entering the eating area.

The ore is mined from underneath the ore body using high pressure water jets. This was developed by Cameco and is referred to as the jet boring system or JBS. More detailed information on this method can be found here. We got to see exactly where this occurs while we were touring underground. We also got to see the area where the engine for the jets of water are kept. They use 15000 psi to retrieve the ore.

Once the ore is removed from the ore body it goes to a slurry tank – which we also got to see. From there it is ground up more to make it easier to move to the surface. Once we returned to the surface, we were taken to the building that the trucks enter to load the slurry that is then moved by truck to McClean Lake for milling.

Our tour guides answered all of our questions and were very patient when they had to re-explain some of the processes more than once. After the tour we loaded up the bus and headed to McClean Lake to see the milling process.

Orano McClean Lake Mill

by: Michelle Wall, Scott Collegiate, Regina and Carolyn Bowler, Sask Polytech, Moose Jaw

After waking up bright and early, the group split up to get on our planes for the ride to Cigar Lake. The tour of the uranium mine was fantastic as you just read above.

A delicious lunch was provided, and then we were on our way to the Orano Processing Facility located at McCLean Lake.

Our bus driver took us through some beautiful countryside full of lakes and black spruce/jack pine forest.

We arrived at the plant, and had coffee and the best fruit tray and snacks while the entertaining Monsieur Vincent Laniece (Gen. Mgr.) gave us an overview of the facility in his charming French accent.

Having a Frenchman in charge ensured that we were dressed to the nines in the latest safety fashions. Red coats, baby blue hats and purple gloves rounded out our ensembles.

Then we were off to the JEB Tailings Management Facility, an impressive 120m hole in the ground that used to be a mine from 1994-1997. Now, the wastes from the plant flow into the pond and settle on the bottom to consolidate into a big plug. Pumps draw water from the bottom to be recycled into the plant. The TMF was designed to ensure that all water flows into the pond from the surrounding area, and around the tailings. The inviting turquoise water is currently at an elevation of 436m. They were in the process of adding a liner made of bentonite clay to the upper portion of the pond to ensure that water flow continues to flow into the pond and not into the environment as the pond rises to its maximum capacity elevation of 450m which will be enough to hold all anticipated tailings from Cigar Lake. The liner also helps to prevent plants from gaining a foothold, which further prevents any wildlife from settling on the pond. With plenty of surrounding lakes to choose from, stray birds have never been a real issue.

We headed back to the plant to learn how the plant deals with the 14-16 truckloads of uranium sent from the Cigar Lake mine each day. An impressive safety record and the array of devices for monitoring alpha, beta and gamma radiation made for a relaxing entry into the plant.

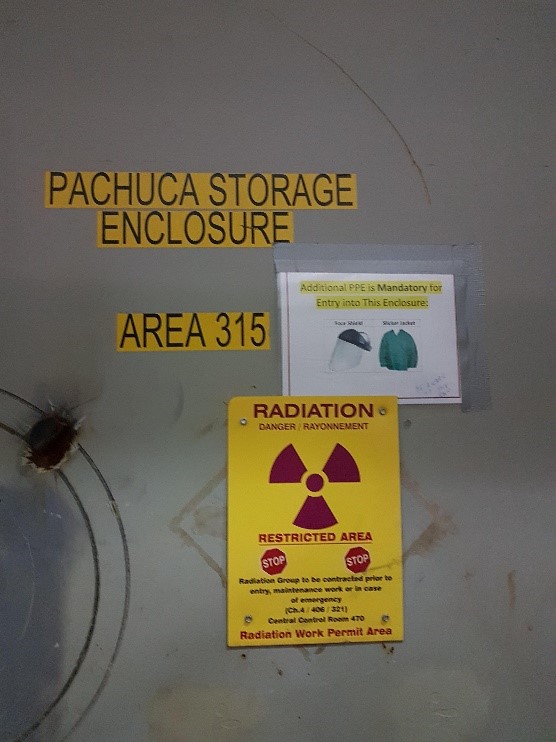

First stop - unloading the trucks. The 12% uranium slurry is vacuum suctioned out of the bottom of each truck container and sent to the pachucas for storage. This area had the highest levels of radiation in the whole plant, so were weren't allowed to enter.

From the pachucas, we went to the leaching area where acid is used to extract uranium, and a variety of other metals, from the slurry. There is a lot of monitoring of the waste stream at this point because elements like selenium (which is toxic to fish at levels measured in parts per BILLION) can be present. As fishing is the main recreation of a lot of the workers here, they make sure that nothing will harm their pastime!

We also learned that a large amount of hydrogen gas can be released from the clay at this step, and the plant had to overhaul their equipment to make sure H levels stayed below the explosive range. Several backup systems make sure the levels stay low, even during the heat of summer.

Day 6 Diamond presentation & SRC Lab Tour, August 24, 2018

by: Renee Mahajan

Check out Renee's blog on the diamond presentations https://mixcord.co/acapella/p/EmN4Fvc34Bqn7omJwJR_Ig/

The 50th Annual Emergency Response Mine Rescue Skills Competition took place on Saturday, June 2, 2018 in Moose Jaw at Mosaic Place and Moose Jaw Exhibition. Here are the results.

The Competition Guidelines can be found here. Click here for the Mine Rescue Manual.

The SMA ERMRC Newletter The Scoop can be found here

NEWS RELEASE

Monday, May 28, 2018

Mining: Sustaining Success

Regina: The Honourable Bronwyn Eyre, Minister of Energy & Resources along with Jessica Theriault, Chair of the Saskatchewan Mining Association launched ‘Mining Week in Saskatchewan’ today at the Saskatchewan Legislature. Mining Week in Saskatchewan runs from May 27 – June 2, 2018.

Saskatchewan is a global mining leader. While low commodity prices have continued to make for challenging operating environment, we are reminded that Saskatchewan is a good place to be operating mines. “Saskatchewan provides a low-risk environment because of both the great geological framework, and also the considered regulatory and policy frameworks. SMA member companies have made multibillion dollar investments in Saskatchewan over the past decade. And because of these investments, mining remains a key pillar of Saskatchewan’s economy.” said Jessica Theriault, Chair of Saskatchewan Mining Association.

As Canada transitions to a lower carbon economy, Saskatchewan products are among the most responsibly mined in the world. “Saskatchewan mining operations feed and fuel the world with their products, improving the quality of life around the world and at home. The world needs more Saskatchewan mineral products and we will continue to work with governments to develop a framework for sustained success in a globally competitive marketplace”, said Pam Schwann, SMA President.

During Mining Week, the Saskatchewan Mining Association will have dozens of events in communities across the province, culminating with the 50th Annual Emergency Response/Mine Rescue Skills Competition, Saturday, June 2nd at Mosaic Place and Moose Jaw Exhibition Grounds in Moose Jaw.

-30-

For further information contact:

Tracey Irwin, SMA Manager, Communications and Membership, (306) 591-7050

News Release: Saskatchewan Mining Week 2018, Mining: Sustaining Success

Saskatchewan Mining Week May 27 - June 2, 2018.

Following is a list of Mining Week activities.

Monday, May 28 – Pierre Gratton, President & CEO, Mining Association of Canada will make a luncheon presentation to the Association of Professional Engineers and Geoscientists of Saskatchewan and Saskatchewan Chamber of Commerce to be held at the Hotel Saskatchewan Radisson Plaza in Regina. https://www.apegs.ca/Portal/Pages/event-details-7/33477

Tuesday, May 29 – Pam Schwann, President, Saskatchewan Mining Association will make a luncheon presentation to members of the Humboldt and District Chamber of Commerce at the Bella Vista in Humboldt. https://www.humboldtchamber.ca/events/details/mining-week-in-saskatchewan-2073

Wednesday, May 30 - Kyle Leadbeater, Superintendent, Dry End Production, K+S Potash Canada will make a breakfast presentation to the Moose Jaw and District Chamber of Commerce at Grant Hall Hotel, Moose Jaw. https://www.mjchamber.com/home

Wednesday, May 30 – Women in Mining/ Women in Nuclear Networking Event with keynote speaker the Honourable Bronwyn Eyre, Minister of Energy & Resources to be held at the Saskatoon Club, Saskatoon. http://wimwinsk.com/event/2018-wimwin-sk-mining-week-networking-event/

Wednesday, May 30 and Thursday, May 31 – ‘Core Days’ in partnership with Keewatin Community Development Association, Northlands College and the Ministry of Energy & Resources. Events include: Technical Discussions, Core and Rock Sample Displays, Long Term Service Awards, Mineral Exploration & Mine Service Tradeshow, La Ronge. http://www.kcdc.ca/coredays/

Thursday, May 31 – Larry Long, Vice President Operations, Potash, Nutrien will make a breakfast presentation to the North Saskatoon Business Association to be held at the Saskatoon Club in Saskatoon. http://nsbasask.com/event/nsba-mining-week-breakfast-may31-18/

Thursday, May 31 – IMII’s 5th Annual “Let’s Talk Minerals!” to be held at the Saskatoon Inn & Conference Centre, Saskatoon. http://www.imii.ca/events/events-details/?tx_ttnews%5Btt_news%5D=208&cHash=8208d01a9013b9e560a50c3419b8d7a6

Friday, June 1 – The Honourable Bronwyn Eyre, Minister of Energy & Resources will make a breakfast presentation to the Greater Saskatoon Chamber of Commerce to be held at the Radisson Hotel, Saskatoon. http://members.saskatoonchamber.com/events/details/saskatchewan-mining-week-breakfast-4100

Saturday, June 2 – 50th Annual Emergency Response/Mine Rescue Skills Competition at Mosaic Place and Moose Jaw Exhibition Park, Moose Jaw.

For more information on Saskatchewan Mining Week contact the SMA office (306) 757-9505; admin@saskmining.ca

TEAM Response and St. John Ambulance will be offering the Train the Trainer Program again this year. The objective of the Train the Trainer program is to better prepare those that are tasked with training a team for competition or participating as a team member.

Pre-requisite for Train the Trainer

Agenda for Train the Trainer

Proposed training date:

April 11th, 2018 at Mosaic Place, 175, 119 River St W, Moose Jaw, SK. The course will run from 8:00 am to 4:30 pm. Lunch will be provided. Anyone with diet restrictions please notify us in advance. Participants can register by email to teamresponse@outlook.com or Michael.Brenholen@sk.sja.ca The cost of the course is $225.00 per person.

Registrations for the Train the Trainer course will be accepted until April 5th, 2018 to allow for course loading.

The 10th Annual Saskatchewan Mining Supply Chain Forum will be held April 10 and 11, 2018 at Prairieland Park in Saskatoon, SK.

This Forum provides information on how manufacturers, construction, equipment and service providers can access mining supply opportunities.

Forum topics have historically included (yet to be finalized for this year):

For more information and to purchase tickets for the10th Annual Saskatchewan Mining Supply Chain Forum please use the following link: https://saskmining.wixsite.com/miningsupplyforum

NOTE: Saskatchewan Mining Association members to contact the SMA office for registration to the event.

Saskatchewan Mining Association's 52nd Annual General Meeting was held on Friday, March 2, 2018 at the Radisson Hotel Saskatoon.

Download the 2017 Annual Report

The 3rd Mine Safety Summit - Technical Aspects of Mine Safety was held on Thursday, March 1, 2018 in conjunction with the SMA AGM on Friday, March 2, 2018.

The format of the Summit utilized case studies from SMA member companies and included reviews of incident investigations, equipment/procedure evaluations, and best practice discussions. Member companies presented for approximately 20 minutes/presentation. The case studies were grouped into themes which relate to activities and conditions that have been, or have the potential to have been, associated with serious injury and/or fatality.

Following are the presentations:

Ben Stevenson & Robin Butler, BHP

Garry Sawkey, K+S Potash Canada

Kathy Sovdi, Westmoreland Coal Company

Chad Binsfeld, K+S Potash Canada

February 7-8, 2018

Plenary Sessions, Break-out Sessions, Case Studies, Trade Show, Poster Session and More!

Topics include: Species at Risk, Climate Change, Mining Restoration/Reclamation, Wetland Restoration, Soil and Phyto Remediation, Grazing and Prescribed Burning and partnerships!

At the Saskatoon Inn, in Saskatoon, SK

More information: 306-352-0472, pcap@sasktel.net or www.pcap-sk.org /ckfinder/userfiles/files/NPRRW18 Advertising Poster.pdf

Global Mining Collaboration Lands in Edmonton this October

An interactive forum dedicated to presentations and discussions around Interoperability, Autonomous Mining, and much more, is taking place October 18-19 at the University of Alberta in Edmonton. Hear from speakers involved in the latest mining industry guideline work on autonomy, data sharing, and cyber security, as well as case studies on success stories outside the industry. You won’t want to miss the spotlight on GMSG’s Underground Mining projects around Battery Electric Vehicles and Short Interval and Real-Time Control.

GMSG forums offer a chance for participants to discover opportunities for their companies to grow and innovate. See the attached agenda for further details./ckfinder/userfiles/files/GMSG_17_EdmontonForum_Agenda.pdf

Following is a blog on the 2017 GeoVenture August 14 - 19, 2017.

Day 1 Monday August 14th, 2017 - Orientation

Day 2 Tuesday August 15th, 2017 - K + S Potash Canada Bethune Mine, by Erika Bakker, Saskatoon Misbah School

Our first day took us to Saskatchewan’s newest mine – K+S Potash Canada in Bethune. We learned about a special kind of mining called “solution mining.” This is very different – but also similar – to conventional mining. The reason you would want to do solution mining over conventional mining is you can reach far deeper ore beds.

In solution mining rather than send people and machines deep underground, you send hot water. At first it is just plain hot water to dissolve both the potash – KCl, and the salt – NaCl. This creates the “pocket” to get started. After you have some space, you send down a brine solution of NaCl and water. This brine is so super-NaCl concentrated, that it cannot dissolve any more salt, only potash. This lets you take only the KCL and leave the NaCl behind. I was surprised to learn about the “diesel blanket,” they pump some diesel into the hole to coat the top, so the water doesn’t dissolve the top of the cavern!

Once you pump the water out of the hole, the process becomes similar to conventional mining. The potash is dried, compacted, and shipped out by rail car to happy customers all over the world… but not before they dye it PINK!

.jpg)

Day 3 Wednesday August 16, 2017 - Westmoreland Coal Poplar River Mine, by Todd Smith, Ecole Ducharme, Moose Jaw and Satindar Nijhawan, Saskatchewan Polytechnic Moose Jaw

What Lies beneath?

Our visit to Westmoreland Coal Company’s Poplar River Mine, was our chance to dig deeper into this important mineral resource that spurs the industry in the Coronach and Estevan area; not to mention provides the fuel to generate base load power for the majority of the province (630 Mega-Watts).

Arriving on site and seeing the scale of the operation surprised us. We traveled to a coal pit where we were able to lay our hands on the remnants of Saskatchewan’s tropical past. Some 300 million years ago, our province was covered in lush rainforest…hard to believe, if you have experienced a Saskatchewan winter! The vegetation was covered in sediments and compacted to create the coal that we now find in the South-East.

After the topsoil is stripped, the dragline removes some 50m of overburden to access the lignite coal seam. The seam is around 4 m thick and is removed from the ground by giant front-end loaders that work around the clock to supply coal to the power plant. While some pits are active, the engineers are hard at work mapping new and existing pits using drones to gain a better view and more accurate measurements. The information is fed in to the GPS units on the dragline to help improve efficiencies.

Once the coal has been extracted, the remediation process begins. This creates very little back log in the reclamation process and makes for a near seamless transition between mined and unmined ground. Habitat for wildlife is restored and the reclaimed land is used to provide hay for local farmers.

The rigorous work of extracting the coal means that preventative maintenance is necessary. While touring the mine, the diversity of jobs available was staggering. Mining engineers, Environmental engineers, Heavy duty mechanics, Welders, Safety officers and Heavy equipment operators are just some of the many job opportunities in the mining field.

After we wrapped up our tour of the mine, we came to the realization that Saskatchewan needs coal! It provides jobs, base load power, and drives our economy. With the increasing concern for “clean energy”, coal should not be a “four letter word”. Saskatchewan leads the world in Carbon Capture technology and coal is still the cleanest option to fill our power needs.

We would like to thank Westmoreland Coal Company and the staff at Poplar River Mine for hosting the SMA GeoVenture program, allowing us to tour the mine site and opening our eyes to the power of coal.

On Thursday morning, we boarded the bus at 6:30am with captain Ryan behind the wheel. We were eager to use our newly gained knowledge of potash mining that we obtained from our fabulous guides at the Esterhazy Potash Interpretive Centre the night before. Our bus was bound for the PotashCorp Rocanville mine where we had the opportunity to tour the underground facilities at the Scissor’s Creek site (following a minor detour).

The PotashCorp Rocanville mine has been in operation since September of 1970 and is the largest underground potash mine in the world. Their ore consists of approximately 1/3 Potassium chloride (aka – the money maker) and 2/3 Sodium chloride and the recent expansion to the facility has increased their capacity to 6.5 million tonnes of potash per year. Those numbers translate into approximately 18,000 tonnes or 200 rail cars of product per day. This production is made possible by approximately 800 employees, 11 mining machines, two processing mills, and a rich deposit of potash.

Once we had received our orientation/safety briefing and were outfitted with our PPE, the real fun began when we headed 3200 feet (approximately one kilometer) below surface! Our knowledgeable tour guides introduced us to their little town below ground and the equipment involved in the conventional mining method used at the Rocanville site. As we travelled around in our electric vehicles through the 8 foot drifts, we had the opportunity to see mechanical shops, offices, a mining machine, other heavy duty equipment, permanent and temporary conveyor belts, the product being mined, and a refuge station. As we explored the tunnels of potash, the warm, dry air and the salt being deposited on our lips (and every other inch of our bodies) quickly became noticeable.

The highlight of the tour was the mining demonstration that gave us the opportunity to see the four massive routers and extendable conveyer belt in action. In order to mine a single drift, the miner completes three alternating and overlapping cuts. As the ore is mined, it is channeled on to the extendable conveyer belt where it begins its journey through the maze of temporary and permanent belts that lead to the two shafts located at the original Rocanville site. The ore is then skipped to surface where it enters the mill and begins the processing required to isolate the potassium chloride which is used to supply a vital nutrient to soils around the world.

PotashCorp Rocanville Underground, by Kunle Adelakun, Saskatchewan Polytechnic Saskatoon

I was privileged to have participated in the 2017 Geoventure program organized by Saskatchewan Mining Association. Here are some of the knowledge I can take to my class as an instructor. Saskatchewan is the heart of Potash mining in the world. The deposit of salts (NaCl and KCl) which precipitated from evaporation of ocean water thousands of years ago spread mainly across southern part of Saskatchewan and down to the northern US state of North Dakota and spread also into the two neighbouring provinces of Alberta and Manitoba. A good portion of the deposit in Southern Saskatchewan could be mined economically at the depth of 3,300 ft (1,000m) below surface using a conventional mining method while the deposit is mined in the area of the province where it is deeper than 3,300 ft (1,000) using solution mining method. There are eight operating conventional Potash mines and three solution mines in Saskatchewan as of today.

The conventional potash mining required sinking of two shafts into the potash bearing formation. One for providing fresh air into the mine and workers access and the other for exhausting the used air out of the mine and moving of raw potash from underground to the processing mill on surface. The potash is mined using a machine manufactured in Saskatchewan called continuous miners and network of extendable and permanent conveyor belt systems. The machine cuts a panel and then cuts 24 rooms in the panel leaving pillars that separate the rooms from one another. The materials that are cut are moved from the cutting face by the machine unto an extendable conveyor belt that extends as the machine advances. This process is repeated in all the production panels and throughout the life span of the mine. The Potash mining has been a huge boost to Saskatchewan economy since it started by creating a lot of employment opportunities and businesses to the contractors in the province and beyond. This tour has given me the opportunity to see how blessed our province is and how much opportunities do exist in our province especially in the mining industry.

PotashCorp Rocanville Mill, by Bernard Krogsgaard, Regina Christian School

Processing KCL

The volume of potash that is processed daily in Saskatchewan is astounding. It was a rewarding experience to learn about the milling techniques.

Initially, the extracted ore (a mixture of halite-NaCl and sylvite-KCL) is crushed to a particle size of 1 centimetre. This aids the separation of the KCL (approximately 30%) from the NaCl (approximately 70%).

A brine is added to the crushed ore in a ratio of 3:7, brine to ore. The brine along with the use of agitators, scrubs clay and other non-soluable matter from the ore crystals. Using a system of sieves or screens, these clay particles are drawn out of the solution. The remaining slurry is used to separate the KCL from the NaCl. It is a very interesting process.

Chemicals are added to the slurry (brine and ore). This is the flotation stage. These reagents attach to the KCL but not to the NaCl. The KCL with the reagents become hydrophobic (repell water) and have a negative surface charge. At the flotation stage, small air bubbles are released below the slurry. The rising air bubbles align to the KCL particles lifting them to the surface. Frother is added to the mixture to reduce surface tension and the KCL crystals (now separated from the NACl) get suspended on the solution and are skimmed off the surface.

Using centrifugal force the brine is separated from the KCL particles. The remaining moisture is removed from the KCL in dryers at a temperature of 200 degrees.

The KCL particles are sized to 'standard' for the international markets and 'granular' is for use in North America. KCL particles that are too big or fine pass through a machine for compaction into sheets which are then broken to produce the 'standard' or 'granular' sizes.

It is now time to ship the tons of potash that is produced hourly.

Separation Anxiety?, by Dave Little, Valley Manor School, Martensville

Imagine a Saskatchewan teacher on his summer holidays nervously poised to tour a facility which is hot, humid, dusty—and noisier than an out-of-control grade 8 classroom. Whatever could possess this fellow to undertake such an uncomfortable excursion in his free time?

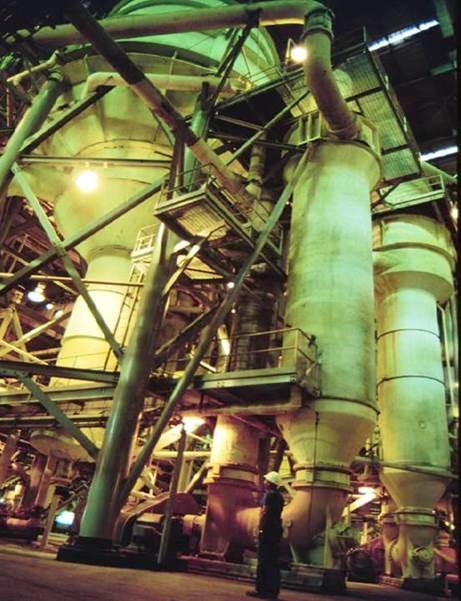

Our story begins almost a kilometre below ground level at the Rocanville potash mine where this fertilizer is produced in quantities greater than anywhere else on the planet. The raw material containing this valuable mineral has rested here undisturbed for 400 million years until quickly mined and rapidly transported by conveyor belt to the bottom of the main shaft. Using a skip, it is transferred at rapid speed—a mere ninety seconds—from its subterranean resting place up to the towering main frame at the surface. Were this potash ore pure enough to be used as a fertilizer, there'd be no need for the hot, dusty, noisy building through which our intrepid teacher will tour.

Alas, the raw material contains only about a third of the desired potash (KCl), so this must be further refined to separate out much salt (NaCl) and other impurities. Thus our anxious Saskatchewan teacher steps into the maelstrom to witness the wonder of separation at the 1970's vintage Rocanville mill. Up and down stairways and through catwalks and hallways, he marvels as the process unfolds.The first step here is to crush the “muck” down to more manageable pieces. Add water and then introduce other chemicals which cause this strange brew to froth and foam and force the potash granules to the top while the salt precipitates to the bottom. A quick paddling sweeps away the KCl pieces from the surface of this soup and a belt speeds them away to a drier. After the drying, screening, and sorting processes, the potash—now pure enough to fertilize hungry crops around the world—is sped off. It soon arrives at either the rail loading facility (which can fill a railcar in ten minutes) or a storage hanger whose enormous size staggers the imagination.

At this point Mr. Saskatchewan teacher—thirst for knowledge assuaged—departs this fascinating locale to water his parched throat, wash the salty dust from his face, and relax in a more tranquil venue for the remainder of his holidays.

Day 5 Friday, August 18, 2017 - Cameco McArthur River, by Laurie Hawkins, Assiniboia Elementary School; Deb De Caux, Dinsmore High School; Tim Vanderhooft, Regina Christian School; David Plaskett, E.D. Feehan High School, Saskatoon; Ryan Gray, Creighton School

Since it was our first time flying into the north, our experience began quickly once we boarded the plane with West Wind Aviation to head to the Athabascan Basin. Once there we would explore the McArthur River Uranium Mine owned by the joint venture of Cameco and AREVA.

Our flight path allowed us to view many topographical transitions as a result of glaciers. As well, we were able to view the meteor impact ring which created Gow Lake, eskers, and drumlins.

After a brief overview of the mine, we learned about exploration. Using helicopters to look for graphite as well as probing on the surface, the exploration crew begins drilling and logging their cores from the top to the bottom. All cores are collected, analyzed, and accounted for. If the correct minerals aren’t found, they move on. We were astounded by the enormous cost of drilling for core samples; anywhere from $30,000 to $500,000 per hole.

The surface tour was very informative. Clearly, McArthur River operates self-sufficiently despite its distance from any other established populations. We had the opportunity to speak with McArthur’s own registered nursing team and their EMT/rescue teams. It was clear that the employees of this mine are well cared for day to day and in the event of emergency situations. We witnessed the technological advance and the increasing automation of systems in the mine as we were toured in the shop, hoist, and central control areas.

After the surface tour, we headed down the wooden shaft to 530m where we boarded vehicles to learn about the process. This cage is used to haul all the equipment that is taken down into the mine. The equipment that is too big to fit in the cage is taken apart and rebuilt down in the shops below. One thing we noted was the wet conditions as well as the cooler temperatures which remain constant all year round at about 12 degrees C. The collection level is at 640m below surface. The roads created below are uneven as they mine based on where the ore is. As they move to different sections, they use the freeze method where they bore holes in the earth in order to run brine into the ground to freeze the ground water. Once they feel as though they have succeeded, they run tests to ensure there are no leaks. Not only do they survey above ground, there are surveys done underground to find the ore body. Once the ore has been collected, it is sent down the road to the Key Lake milling location.

Safety is a very important aspect for the mine. From strict PPE equipment to wash stations, the employees take every precaution to ensure everyone’s safety. Of course the perception for many is the dangerous levels of radiation that employees are exposed to however with the PRISM monitoring system in many locations as well as personal monitors that each person must wear, employees are well below the government level of 50 mSv and even the company level of 20mSv. They use many different aspects to ensure safety such as remote control vehicles, wash stations, scanning the load prior sending it to the top to ensure the proper %, and of course training. Other safety aspects include mesh to protect them from falling debris and to make the structure safe and secure, spraying shotcrete to make walls stronger, and refuge stations every 500 m.

The highlight of the tour was the opportunity to actually see the unconformity! This is where the ore is actually encased. Only a small group of people ever get the opportunity to see this up close, but we have now joined this select group. Both we and the tour guides were excited to experience this together!

From start to finish, and in discussion afterwards, we all agree that a tour of the McArthur River uranium mine is a fantastic opportunity. Anyone who is afforded the opportunity to take part, ought to do so!

NEWS RELEASE

Mining in Transformational Times

Monday, May 29, 2017, Regina: The Honourable Dustin Duncan, Minister of Energy & Resources along with Jessica Theriault, Chair of the Saskatchewan Mining Association launched ‘Mining Week in Saskatchewan’ today at the Saskatchewan Legislature. Mining Week in Saskatchewan runs from May 28 – June 3, 2017.

Today, Saskatchewan is recognized as the world’s #1 jurisdiction for attracting mineral investment according to the annual Fraser Institute Survey of Mining Companies. “Saskatchewan provides a low-risk environment because of both the great geological framework, and also the considered regulatory and policy frameworks. SMA member companies have made multibillion dollar investments in Saskatchewan over the past decade. And because of these investments, mining remains a key pillar of Saskatchewan’s economy in these transformational times”, said Jessica Theriault, Chair of Saskatchewan Mining Association.